§770.20 测试要求

(a) General requirements.

(a)一般要求

(1) All panels must be tested in an unfinished condition, prior to the application of a finishing or topcoat, as soon as possible after their production but no later than 30 calendar days after production.

(1)所有面板生产商必须在生产后尽快在涂装面漆或面漆之前进行测试,但不得晚于生产后30个日历日。

(2) Facilities that conduct the formaldehyde testing required by this section must follow the procedures and specifications, such as testing conditions and loading ratios, of the test method being used.

(2)进行本节要求的甲醛检测的设施必须遵循所用试验方法的程序和规范,如试验条件和装载比例。

(3) All equipment used in the formaldehyde testing required by this section must be calibrated and otherwise maintained and used in accordance with the equipment manufacturer's instructions.

(3)本节要求的所有甲醛检测设备必须按照设备制造商的说明进行校准和维护。

(b) Quality control testing—

(b)质量控制测试 -

(1) Allowable methods. Quality control testing must be performed using any of the following methods, with a showing of correlation for each method pursuant to paragraph (d) of this section:

(1)允许的方法。 必须使用以下任何一种方法进行质量控制测试,并根据本节(d)段显示每种方法的相关性:

(i) ASTM D6007-14 (incorporated by reference, see §770.99).

(i)ASTM D6007-14(以参照并入,参见§770.99)。

(ii) ASTM D5582-14 (incorporated by reference, see §770.99).

(ii)ASTM D5582-14(以参照并入,参见§770.99)。

(iii) BS EN ISO 12460-3:2015 E (Gas Analysis Method) (incorporated by reference, see §770.99).

(iii)BS EN ISO 12460-3:2015 E(气体分析方法)(以参照并入,参见§770.99)。

(iv) DMC 2007 User's Manual (incorporated by reference, see §770.99).

(iv)DMC 2007用户手册(以参照并入,见§770.99)。

(v) DMC 2012 GP User's Manual (incorporated by reference, see §770.99).

(v)DMC 2012 GP用户手册(以参照并入,见§770.99)。

(vi) BS EN ISO 12460-5:2015 E (Perforator Method) (incorporated by reference, see §770.99).

(vi)BS EN ISO 12460-5:2015 E(穿孔器方法)(以参照并入,参见§770.99)。

(vii) JIS A 1460:2015(E) (24-hr Desiccator Method) (incorporated by reference, see §770.99).

(vii)JIS A 1460:2015(E)(24小时干燥器方法)(以参照并入,参见§770.99)。

(2) Frequency of testing.

(2)测试频率。

(i) Particleboard and medium-density fiberboard must be tested at least once per shift (eight or twelve hours, plus or minus one hour of production) for each production line for each product type. Quality control tests must also be conducted whenever:

(i)对于每种产品类型的每条生产线,刨花板和中密度纤维板必须每班至少测试一次(8或12小时,正负1小时的生产)。 质量控制测试也必须在以下情况下进行:

(A) A product type production ends, even if eight hours of production has not been reached;

(A)产品类型生产结束,即使没有达到八小时的生产;

(B) The resin formulation is changed so that the formaldehyde to urea ratio is increased;

(B)改变树脂配方,使甲醛与尿素的比例增加;

(C) There is an increase by more than ten percent in the amount of formaldehyde resin used, by square foot or by panel;

(C)所用甲醛树脂的量,按平方英尺或按面板,增加了10%以上

(D) There is a decrease in the designated press time by more than 20%; or

(D)指定的印刷时间减少超过20%,或

(E) The quality control manager or quality control employee has reason to believe that the panel being produced may not meet the requirements of the applicable standards.

(E)质量控制经理或质量控制员工有理由确信所生产的面板可能不符合适用标准的要求。

(ii) Particleboard and medium-density fiberboard panel producers are eligible for reduced quality control testing if they demonstrate consistent operations and low variability of test values.

(ii)如果刨花板和中密度纤维板生产商表现出一致的操作和低测试值的可变性,则他们有资格进行质量控制测试。

(A) To qualify, panel producers must:

(A)要获得资格,面板生产商必须:

(1) Apply in writing to an EPA TSCA Title VI TPC; and

(1)以书面形式向EPA TSCA Title VI TPC提出申请;和

(2) Maintain a 30 panel running average.

(2)保持30个面板的平均运行。

(B) With respect to reduced quality control testing, EPA TSCA Title VI TPCs:

(B)关于减少质量控制测试,EPA TSCA Title VI TPC:

(1) May approve a reduction to one quality control test per 24-hour production period if the 30 panel running average remains two standard deviations below the designated QCL for the previous 60 consecutive calendar days or more;

(1)如果30个面板运行平均值在前60个连续日历日或更长时间内保持低于指定QCL的两个标准差,则可批准每24小时生产期减少一次质量控制测试;

(2) May approve a reduction to one quality control test per 48-hour production period if the 30 panel running average remains three standard deviations below the designated QCL for the previous 60 consecutive calendar days or more;

(2)如果30个面板运行平均值在前60个连续日历日或更长时间内保持低于指定QCL的三个标准差,则可批准每48小时生产期减少一次质量控制测试;

(3) Will approve a request for reduced quality control testing as long as the data submitted by the panel producer demonstrate compliance with the criteria and the EPA TSCA Title VI TPC does not otherwise have reason to believe that the data are inaccurate or the panel producer's production processes are inadequate to ensure continued compliance with the emission standards; and

(3)只要面板生产商提交的数据证明符合标准并且EPA TSCA Title VI TPC没有理由相信面板生产商的数据不准确或生产过程不足以确保继续符合排放标准,那么将批准减少质量控制测试的请求;和

(4) Will revoke approval for reduced quality control testing if testing or inspections indicate a panel producer no longer demonstrates consistent operations and low variability of test values.

(4)如果测试或检查表明面板生产商不再表现出操作的一致性和测试值的低变异性,将撤销对减少质量控制测试的批准。

(iii) Hardwood plywood must be tested as follows:

(iii)硬木胶合板必须按如下方式进行测试:

(A) At least one test per week per product type if the weekly hardwood plywood production at the panel producer is more than 100,000 but less than 200,000 square feet.

(A)如果面板生产商每周硬木胶合板的产量超过100,000但小于200,000平方英尺,则每种产品类型每周至少进行一次测试。

(B) At least two tests per week per product type if the weekly hardwood plywood production at the panel producer is 200,000 square feet or more, but less than 400,000 square feet.

(B)如果面板生产商每周硬木胶合板的产量为200,000平方英尺或更多,但小于400,000平方英尺,则每种产品类型每周至少进行两次测试。

(C) At least four tests per week per product type if the weekly hardwood plywood production at the panel producer is 400,000 square feet or more.

(C)如果面板生产商每周硬木胶合板的产量为400,000平方英尺或更多,则每种产品类型每周至少进行四次测试。

(D) If weekly production of hardwood plywood at the panel producer is 100,000 square feet or less, at least one test per 100,000 square feet for each product type produced; or, if less than 100,000 square feet of a particular product type is produced, one quality control test of that product type every month that it is produced.

(D)如果面板生产商每周生产的硬木胶合板为100,000平方英尺或更少,每种产品类型每100,000平方英尺至少进行一次测试;或者,如果生产的产品类型少于100,000平方英尺,则生产一种产品类型,每个月进行一次质量控制测试。

(E) Quality control tests must also be conducted whenever:

(E)质量控制测试也必须在以下情况下进行:

(1) The resin formulation is changed so that the formaldehyde to urea ratio is increased;

(1)改变树脂配方,使甲醛与尿素的比例增加;

(2) There is an increase by more than ten percent in the amount of formaldehyde resin used, by square foot or by panel;

(2)所用甲醛树脂的量,按平方英尺或按面板,增加了10%以上

(3) There is an increase by more than 20% in the adhesive application rate;

(3)粘合剂涂布率增加20%以上;

(4) There is a decrease in the designated press time by more than 20%; or

(4)指定的印刷时间减少20%以上;或

(5) The quality control manager or quality control employee has reason to believe that the panel being produced may not meet the requirements of the applicable standard.

(5)质量控制经理或质量控制员工有理由相信所生产的面板可能不符合适用标准的要求。

(iv) Composite wood products that have been approved by an EPA TSCA Title VI TPC or CARB for reduced testing under §770.18(b) through (c) must be tested at least once per week per product type and, for particle board and medium-density fiberboard, per production line, for products produced that week, except that hardwood plywood panel producers who qualify for less frequent testing under paragraph (b)(2)(iii)(D) of this section may continue to perform quality control testing under that provision.

(iv)经EPA TSCA Title VI TPC或CARB批准的复合木制品,根据§770.18(b)至(c)进行减少测试,每个产品类型必须至少每周测试一次,对于每条生产线的刨花板和介质密度纤维板,用于本周生产的产品,除了根据本条(b)(2)(iii)(D)段有资格进行较不频繁测试的硬木胶合板生产商可继续根据该条款进行质量控制测试。

(3) Results. Any test result that exceeds the QCL established pursuant to §770.7(c)(4)(i)(C) must be reported to the EPA TSCA Title VI TPC in writing within 72 hours. The panel producer must comply with §770.22 with respect to any lot represented by a quality control sample that exceeds the QCL. Where multiple products are grouped in a single product type for testing, this includes all products in the group represented by the sample.

(3)结果。任何超过根据§770.7(c)(4)(i)(C)建立的QCL的测试结果必须在72小时内以书面形式向EPA TSCA Title VI TPC报告。面板生产商必须遵守§770.22关于质量控制样本超过QCL的任何批次。如果将多个产品分组到单个产品类型中进行测试,则包括样本所代表的组中的所有产品。

(c) Quarterly testing. Quarterly testing must be supervised by EPA TSCA Title VI TPCs and performed by TPC laboratories.

(c)季度测试。季度测试必须由EPA TSCA Title VI TPC监督并由TPC实验室执行。

(1) Allowable methods. Quarterly testing must be performed using ASTM E1333-14 (incorporated by reference, see §770.99) or, with a showing of equivalence pursuant to paragraph (d) of this section, ASTM D6007-14 (incorporated by reference, see §770.99).

(1)允许的方法。季度测试必须使用ASTM E1333-14(以参照并入,参见§770.99)或根据本节(d)段的等效性显示ASTM D6007-14(以参照并入,参见§770.99)进行。

(2) Sample selection.

(2)样品选择。

(i) Samples must be randomly chosen by an EPA TSCA Title VI TPC.

(i)样品必须由EPA TSCA Title VI TPC随机选择。

(ii) Samples must be selected from each certified product type for quarterly testing purposes. For hardwood plywood samples, the samples must be randomly selected from products that represent the range of formaldehyde emissions of products produced by the panel producer.

(ii)必须从每种认证产品类型中选择样品进行季度测试。对于硬木胶合板样品,样品必须从代表面板生产商生产的产品的甲醛释放范围的产品中随机选择。

(iii) Samples must not include the top or the bottom composite wood product of a bundle.

(iii)样品不得包括整束的顶部或底部复合木制品。

(3) Sample handling. Samples must be closely stacked or air-tight wrapped between the time of sample selection and the start of test conditioning. Samples must be labeled as such, signed by the EPA TSCA Title VI TPC, bundled air-tight, wrapped in polyethylene, protected by cover sheets, and promptly shipped to the TPC laboratory. Conditioning must begin as soon as possible, but no later than 30 calendar days after the samples were produced.

(3)样品处理。在样品选择和测试调节开始之间,样品必须紧密堆叠或紧密包裹。样品必须贴上标签,由EPA TSCA Title VI TPC签字,气密捆绑,用聚乙烯包裹,用盖板保护,并立即运到TPC实验室。调节必须尽快开始,但不得晚于样品生产后30个日历日。

(4) Results. Any sample that exceeds the applicable formaldehyde emission standard in §770.10 must be reported by the EPA TSCA Title VI TPC to the panel producer in writing and to EPA, in accordance with §770.8, within 72 hours. The panel producer must comply with §770.22 with respect to any lot represented by a sample result that exceeds the applicable formaldehyde emission standard. Where multiple products are grouped in a single product type for testing, this includes all products in the group represented by the sample.

(4)结果。任何超过§770.10中适用的甲醛释放标准的样品必须由EPA TSCA Title VI TPC以书面形式报告给面板生产商,并按照§770.8在72小时内报告给EPA。面板生产者必须遵守§770.22关于样本结果超出适用的甲醛排放标准的任何批次。如果将多个产品分组到单个产品类型中进行测试,则包括样本所代表的组中的所有产品。

(5) Reduced testing frequency. Composite wood products that have been approved by an EPA TSCA Title VI TPC or CARB for reduced testing under §770.18(c) need only undergo quarterly testing every six months.

(5)降低测试频率。经EPA TSCA Title VI TPC或CARB批准的复合木制品,根据§770.18(c)进行的减少测试只需每六个月进行一次季度测试。

(d) Equivalence or correlation. Equivalence or correlation between ASTM E1333-14 (incorporated by reference, see §770.99) and any other test method used for quarterly or quality control testing must be demonstrated by EPA TSCA Title VI TPCs or panel producers, respectively, at least once each year for each testing apparatus or whenever there is a significant change in equipment, procedure, or the qualifications of testing personnel. Once equivalence or correlation have been established for three consecutive years, equivalence or correlation must be demonstrated every two years or whenever there is a significant change in equipment, procedure, or the qualifications of testing personnel.

(d)等同或相关。ASTM E1333-14(以参照并入,见§770.99)和用于季度或质量控制测试的任何其他测试方法之间的等效性或相关性必须分别由EPA TSCA Title VI TPC或面板生产商每年至少证明一次,每个测试设备或每当设备,程序或测试人员的资格发生重大变化时。一旦连续三年建立等效性或相关性,必须每两年,每当设备,程序或测试人员的资格发生重大变化时,必须证明等效性或相关性。

(1) Equivalence between ASTM E1333-14 and ASTM D6007-14 when used by the TPC for quarterly testing. Equivalence must be demonstrated for at least five comparison sample sets, which compare the results of the two methods. Equivalence must be demonstrated for each small chamber used and for the ranges of emissions of composite wood products tested by the TPC.

(1)当TPC用于季度测试时,ASTM E1333-14和ASTM D6007-14之间等效。必须证明至少五个比较样本集的等效性,比较两种方法的结果。必须证明每个小室使用的等效性以及TPC测试的复合木制品的排放范围。

(i) Samples. (A) For the ASTM E1333-14 method (incorporated by reference, see §770.99), each comparison sample must consist of the result of testing panels, using the applicable loading ratios specified in the ASTM E1333-14 method (incorporated by reference, see §770.99), from similar panels of the same product type tested by the ASTM D6007-14 method (incorporated by reference, see §770.99).

(i)样品。(A)对于ASTM E1333-14方法(以参照并入,参见§770.99),每个对比样品必须包括测试板的结果,使用ASTM E1333-14方法中指定的适用加载比(遗产找并入, 参见§770.99),来自ASTM D6007-14方法测试的相同产品类型的类似面板(以参照并入,参见§770.99)。

(B) For the ASTM D6007-14 method (incorporated by reference, see §770.99), each comparison sample shall consist of testing specimens representing portions of panels similar to the panels tested in the ASTM E1333-14 method (incorporated by reference, see §770.99) and matched to their respective ASTM E1333-14 method (incorporated by reference, see §770.99) comparison sample result. The ratio of air flow to sample surface area specified in ASTM D6007-14 (incorporated by reference, see §770.99) must be used.

(B)对于ASTM D6007-14方法(以参照并入,参见§770.99),每个对比样品应包括代表与ASTM E1333-14方法中测试的面板类似的面板部分的测试样品(以参照并入,参见 §770.99)并与其各自的ASTM E1333-14方法(以参照并入,见§770.99)对比样品结果。必须使用ASTM D6007-14中规定的空气流量与样品表面积的比率(以参照并入,参见§770.99)。

(C) The five comparison sample must consist of testing a minimum of five sample sets as measured by the ASTM E1333-14 method (incorporated by reference, see §770.99).

(C)五个比较样本必须包括测试至少五个样品组,这些样品组通过ASTM E1333-14方法测量(以参照并入,参见§770.99)。

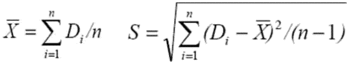

(ii) Average and standard deviation. The arithmetic mean, x, and standard deviation, S, of the difference of all comparison sets must be calculated as follows:

(ii)平均值和标准差。 所有比较集的差值的算术平均值x和标准差S必须计算如下:

Where x = arithmetic mean; S = standard deviation; n = number of sets; D i = difference between the ASTM E1333-14 and ASTM D6007-14 method (incorporated by reference, see §770.99) values for the i th set; and i ranges from 1 to n.

其中x =算术平均值;S =标准差;n =集合数;D i =第i组的ASTM E1333-14和ASTM D6007-14方法(以参照并入,参见§770.99)之间的差值;i的范围从1到n。

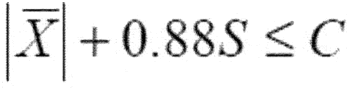

(iii) Equivalence determination. The ASTM D6007-14 method (incorporated by reference, see §770.99) is considered equivalent to the ASTM E1333-14 method (incorporated by reference, see §770.99) if the following condition is met:

(iii)等同性确定。 如果满足以下条件,则ASTM D6007-14方法(以参照并入,参见§770.99)被认为等同于ASTM E1333-14方法(以参照并入,参见§770.99):

Where C is equal to 0.026.

其中C等于0.026。

(2) Correlation between ASTM E1333-14 and any quality control test method. Correlation must be demonstrated by establishing an acceptable correlation coefficient (“r” value).

(2)ASTM E1333-14与任何质量控制测试方法之间的相关性。 必须通过建立可接受的相关系数(“r”值)来证明相关性。

(i) Correlation. The correlation must be based on a minimum sample size of five data pairs and a simple linear regression where the dependent variable (Y-axis) is the quality control test value and the independent variable (X-axis) is the ASTM E1333-14 (incorporated by reference, see §770.99) test value or, upon a showing of equivalence in accordance with paragraph (d) of this section, the equivalent ASTM D6007-14 (incorporated by reference, see §770.99) test value. Either composite wood products or formaldehyde emissions reference materials can be used to establish the correlation.

(i)相关性。相关性必须基于五个数据对的最小样本量和简单的线性回归,其中因变量(Y轴)是质量控制测试值,自变量(X轴)是ASTM E1333-14( 以参照并入,参见§770.99)测试值,或者在根据本节(d)的等效性显示时,等效ASTM D6007-14(以参照并入,参见§70.99)测试值。可以使用复合木制品或甲醛释放参考材料来建立相关性。

(ii) Minimum acceptable correlation coefficients (“r” values). The minimum acceptable correlation coefficients are as follows, where “n” is equal to the number of data pairs, and “r” is the correlation coefficient:

(ii) 最小可接受的相关系数(“r”值)。 最小可接受的相关系数如下,其中“n”等于数据对的数量,“r”是相关系数:

|

Degrees of freedom (n-2) 自由配比 |

“r” value r值 |

|

3 |

0.878 |

|

4 |

0.811 |

|

5 |

0.754 |

|

6 |

0.707 |

|

7 |

0.666 |

|

8 |

0.632 |

|

9 |

0.602 |

|

10 or more |

0.576 |

(iii) Variation from previous results. If data from an EPA TSCA Title VI TPC's quarterly test results and a panel producer's quality control test results do not fit the previously established correlation, the panel producer must have its TPC establish a new correlation and new QCLs.

与以前的结果不同。 如果来自EPA TSCA Title VI TPC的季度测试结果和面板生产商的质量控制测试结果的数据不符合先前建立的相关性,则面板生产者必须使其TPC建立新的相关性和新的QCL。

(iv) Failed quarterly tests. If a panel producer fails two quarterly tests in a row for the same product type, the panel producer must have its TPC establish a new correlation curve.

(iv)季度测试失败。 如果面板生产商对同一产品类型连续两次季度测试失败,则面板生产商必须让其TPC建立新的相关曲线。

(e) Quality assurance and quality control requirements for panel producers. Panel producers are responsible for product compliance with the applicable emission standards.

(e) 面板生产商的质量保证和质量控制要求。面板生产商负责产品符合适用的排放标准。

声明:以上内容为临安科达认证技术咨询服务有限公司原创内容,如需转载,请标明出处,谢谢!